If that's the case, then keep stitching on the panels. It'll correct itself.Teddy Madison wrote:I get it!

If you trace a line down the vertical center line on #1 you will see that it diverges away from the center line on #2 as you head towards the bottom.

Looks like there isn't enough hull there to worry yet and the bottom is just twisting.

Dan's Pelagic

-

jem

- Site Admin

- Posts: 4915

- Joined: Fri Jun 18, 2004 8:14 pm

- Type of boat I like: Wooden

- Location: Greensboro, NC

- Contact:

-Matt. Designer.

-

AlohaDan

- Posts: 293

- Joined: Sun Apr 15, 2007 9:36 pm

- Type of boat I like: <-- Please read instructions to the left and delete this text. Then, tell us what type boat you like! :-)

Preliminary dye tests using Transfast dyes discussed at:

viewtopic.php?t=2290

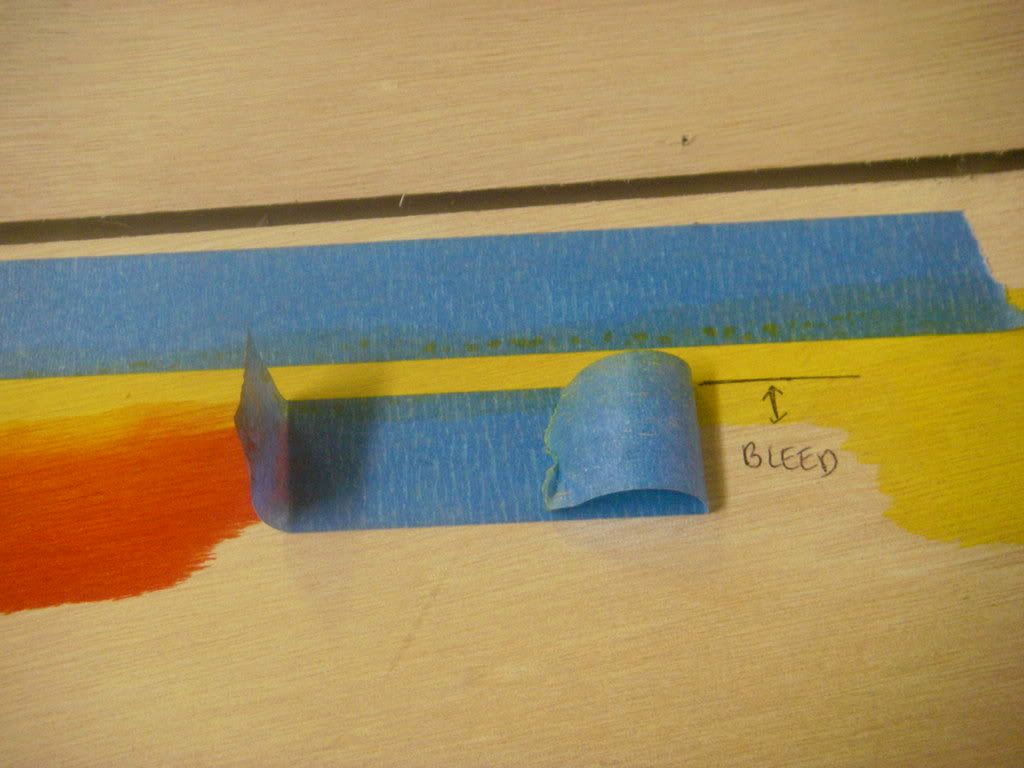

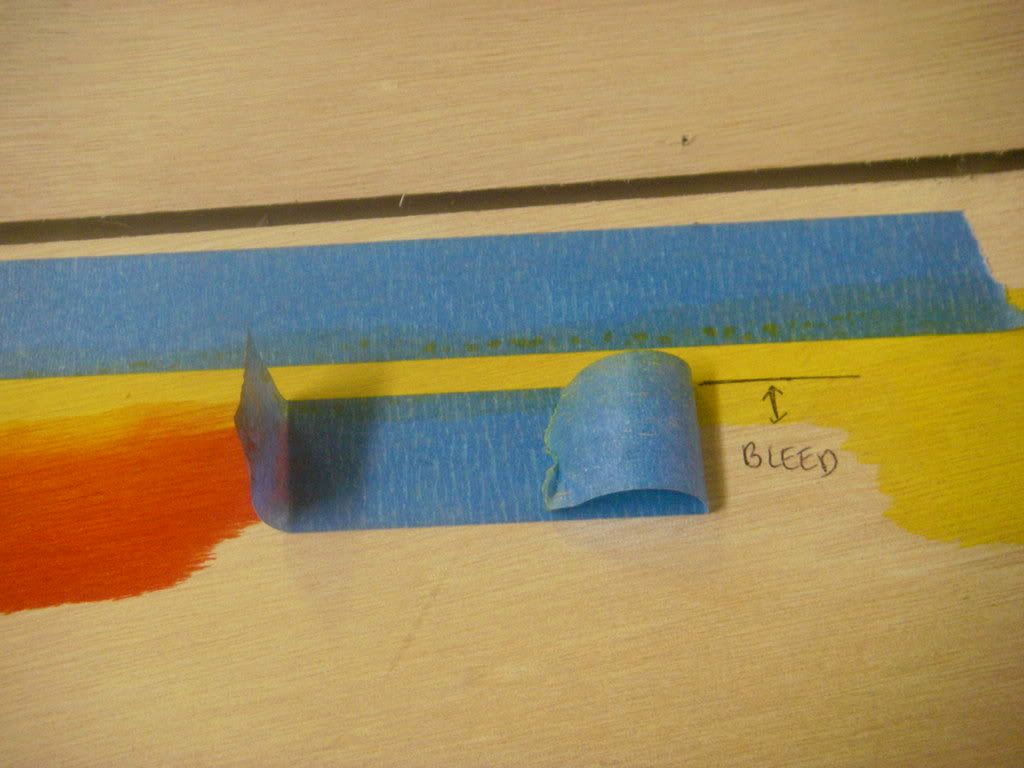

First pic shows a severe bleed problem for red. Evidently the water carries the dye fairly far in the grain.

Second photo shows same bleed with yellow.

Far left is an attempt to get a blending suitable for a "rainbow" effect. Some possibilities there, but I'm not up to it.

Note I haven't shown any richer colors by adding more dye to solution or soften any up by diluting with more water. These are other color possibilities.

But bleed in essence elimnates stright line color changes.

To be able to bring wood grain through with color, using West System 207, will require whole panel to be dyed.

There might be an option of mixing a color in with the actual epoxy. Dyes exist for this purpose. You would have to run another bleed test to see if epoxy gives you a straight line differential over the water based stuff..I don't think you would get that much improvement over water base dying. And I'm not sure how much color in the actual epoxy itself would reduce effect of bringing wood grain through. I'll leave that puzzle to others

But I will in next few days attempt to cover these samples alternating with 206 and 207.

For those interested in exploring dying further, Transfast recommends: The Complete Illustrated Guide to Finishing by Jeff Jewitt.

viewtopic.php?t=2290

First pic shows a severe bleed problem for red. Evidently the water carries the dye fairly far in the grain.

Second photo shows same bleed with yellow.

Far left is an attempt to get a blending suitable for a "rainbow" effect. Some possibilities there, but I'm not up to it.

Note I haven't shown any richer colors by adding more dye to solution or soften any up by diluting with more water. These are other color possibilities.

But bleed in essence elimnates stright line color changes.

To be able to bring wood grain through with color, using West System 207, will require whole panel to be dyed.

There might be an option of mixing a color in with the actual epoxy. Dyes exist for this purpose. You would have to run another bleed test to see if epoxy gives you a straight line differential over the water based stuff..I don't think you would get that much improvement over water base dying. And I'm not sure how much color in the actual epoxy itself would reduce effect of bringing wood grain through. I'll leave that puzzle to others

But I will in next few days attempt to cover these samples alternating with 206 and 207.

For those interested in exploring dying further, Transfast recommends: The Complete Illustrated Guide to Finishing by Jeff Jewitt.

-

pogue3one

- Posts: 64

- Joined: Fri Jun 22, 2007 5:15 pm

- Type of boat I like: <-- Please read instructions to the left and delete this text. Then, tell us what type boat you like! :-)

- Location: Katy, TX

Okay, I did a few tests with some epoxy tints that weren't successful for my needs. However this is what I found: If you were to tape the wood that you want to stain(the intended stained surface is masked) and put a very light coat of epoxy outside of the mask, it tends to make that wood resistant to any coloring. Once that is done, Mask over the lightly epoxied area, leaving the bare wood that you want to stain exposed. Do not stain! Use epoxy colored with an epoxy clear tint. It does not bleed as much as thin stains.

In my test strips of wood, any piece of wood that had any cured epoxy on it, took no color from the tinted epoxy. At least, if I wanted piece of wood with cured epoxy to have any color, I would have to apply several coats. Whereas if the wood was bare, it took the color like it was being stained. Also, on the bare wood that I tested (one simple brush stroke with tinted epoxy) the color did not bleed out of the epoxy. In other words, If you can keep the epoxy itself from bleeding, the color will only saturate as far as the resin will.

I was struck with the idea of tinting the epoxy to have a very uniquely colored wood finish. Unfortunately, I had already done my butt-joints. The wood outside of the cured epoxy stained nicely. The wood covered in cured epoxy was not effected by the coloring.

If one were to use this information, your best bet would to be to color the wood before tacking, joining or anything else that involves epoxy. You might even consider using the tint in the fillet mix. for an interesting contrast.

By the way, the idea for painting my Kayak yellow and calling it the yellow peril came from vintage warplane paint schemes. I thought that the geometric/angular panels were reminiscent of a world war I era biplane fusilage. I wanted to use one of the vintage camo schemes. The only reason I didn't do this, is that it would have been expensive. I settled on a single color scheme of the "yellow peril" which was a training plane used in wwII.

This is what I wanted to do:

As you can see I wanted lines similar to the ones you speak of. If I were to spend the money on so many colors I would find a way to measure and tape the lines prior to applying any epoxy. Unfortunately, as anyone who has tried to pre-drill stitch holes can tell you, things may not line up. However, if none of your lines cross a seam, it would be a whole lot easier.

Here is a link for the clear(not opaque) tint I'm talking about: http://surfsource.net/Manufacturing/Res ... sories.htm

Page down to the "surf source" resin tints in the 2 and 8 ounce bottles.

In my test strips of wood, any piece of wood that had any cured epoxy on it, took no color from the tinted epoxy. At least, if I wanted piece of wood with cured epoxy to have any color, I would have to apply several coats. Whereas if the wood was bare, it took the color like it was being stained. Also, on the bare wood that I tested (one simple brush stroke with tinted epoxy) the color did not bleed out of the epoxy. In other words, If you can keep the epoxy itself from bleeding, the color will only saturate as far as the resin will.

I was struck with the idea of tinting the epoxy to have a very uniquely colored wood finish. Unfortunately, I had already done my butt-joints. The wood outside of the cured epoxy stained nicely. The wood covered in cured epoxy was not effected by the coloring.

If one were to use this information, your best bet would to be to color the wood before tacking, joining or anything else that involves epoxy. You might even consider using the tint in the fillet mix. for an interesting contrast.

By the way, the idea for painting my Kayak yellow and calling it the yellow peril came from vintage warplane paint schemes. I thought that the geometric/angular panels were reminiscent of a world war I era biplane fusilage. I wanted to use one of the vintage camo schemes. The only reason I didn't do this, is that it would have been expensive. I settled on a single color scheme of the "yellow peril" which was a training plane used in wwII.

This is what I wanted to do:

As you can see I wanted lines similar to the ones you speak of. If I were to spend the money on so many colors I would find a way to measure and tape the lines prior to applying any epoxy. Unfortunately, as anyone who has tried to pre-drill stitch holes can tell you, things may not line up. However, if none of your lines cross a seam, it would be a whole lot easier.

Here is a link for the clear(not opaque) tint I'm talking about: http://surfsource.net/Manufacturing/Res ... sories.htm

Page down to the "surf source" resin tints in the 2 and 8 ounce bottles.

Wadefish (complete)

-

Teddy Madison

- Posts: 79

- Joined: Thu Apr 24, 2008 4:36 pm

- Type of boat I like: <-- Please read instructions to the left and delete this text. Then, tell us what type boat you like! :-)

- Location: Rhode Island, United States

-

_AL_

- Posts: 53

- Joined: Sat Mar 08, 2008 8:23 pm

- Type of boat I like: <-- Please read instructions to the left and delete this text. Then, tell us what type boat you like! :-)

- Location: Sydney, Australia

Dan,

I take it you want 2 colours to butt up against each other?

Have you considered the dye you're using & a pinstripe to cover the bleeding?

Given that the dye is water based I don't see how you can stop the bleed without buggering yourself for the 2nd colour.

You could try scoring the outer layer however this will probably weaken the boat (Mat will know).

Can you use a different solvent with the dye? something that won't soak into the wood as easily?

The other option is to have your colour breaks at the joint of 2 panels.

Sorry, not really a solution, just trying to think outside the box.

Al

I take it you want 2 colours to butt up against each other?

Have you considered the dye you're using & a pinstripe to cover the bleeding?

Given that the dye is water based I don't see how you can stop the bleed without buggering yourself for the 2nd colour.

You could try scoring the outer layer however this will probably weaken the boat (Mat will know).

Can you use a different solvent with the dye? something that won't soak into the wood as easily?

The other option is to have your colour breaks at the joint of 2 panels.

Sorry, not really a solution, just trying to think outside the box.

Al

-

Teddy Madison

- Posts: 79

- Joined: Thu Apr 24, 2008 4:36 pm

- Type of boat I like: <-- Please read instructions to the left and delete this text. Then, tell us what type boat you like! :-)

- Location: Rhode Island, United States

-

jem

- Site Admin

- Posts: 4915

- Joined: Fri Jun 18, 2004 8:14 pm

- Type of boat I like: Wooden

- Location: Greensboro, NC

- Contact:

Any and all questions are fair game. If you thought to say it, chances are 3 other builders had the same thought/question.AlohaDan wrote:Teddy spotted it.

Also shows up in the top section of the cross pieces diverging.

Have two guys telling me to put in more cross pieces before screaming. Will do.

Running dye tests now.

Aloha

Dan

-Matt. Designer.

-

AlohaDan

- Posts: 293

- Joined: Sun Apr 15, 2007 9:36 pm

- Type of boat I like: <-- Please read instructions to the left and delete this text. Then, tell us what type boat you like! :-)

Sorry I'm late. Guess I didn't check notify of reply on my last post.

First let me give color objectives:

1. Although you color wood, wood grain comes through for visual appealing effect.

2. Avoid weight of paint. Weight of dye is miniscule.

3. Specific to this yak, University of Hawaii colors.

Poque says:

If one were to use this information, your best bet would to be to color the wood before tacking, joining or anything else that involves epoxy

I agree completely. I didn't get on this bandwagon until I had done the butt joints. Fortunately after applying only fibreglass splice butt re-inforcement on one side, I recognized I should leave off outside hull splice until dye was applied. So if using wood dyes do them first as pogue says.

Pics (will come later) show epoxy sploches before I corrected some of them.

Note on red panel I had applied glass splice. It won't color up.

Two potential fixes. Dying glass when covering outside hull. OR ... Using epoxy dye.

I'll test glass dying solution, but think it will bleed just like wood. Not sure how you would get the dyed portion properly positioned anyway.

The dye in the epoxy itself should work as poque says..but I believe it will act like paint and block out wood grain. I can live with that in stitch holes and small section of this panel as it will be near waterline. We will see.

poque thanks for the tint source.

AL

I take it you want 2 colours to butt up against each other?

Yep. And due to complexity of doing colors have chosen to do separate panel colors as you also spotted as a solution.

Have you considered the dye you're using & a pinstripe to cover the bleeding?

Yes reflective tape stripping. But you never know how wide bleed will be.

Given that the dye is water based I don't see how you can stop the bleed without buggering yourself for the 2nd colour.

True enough. Why I went with separate panel colors

You could try scoring the outer layer however this will probably weaken the boat (Mat will know).

Can you use a different solvent with the dye? something that won't soak into the wood as easily?

Going to pass on those thought, but thanks for your ideas.

Mick & others I'll be adding more cross panels this week,

But man does not live by building boats. Gotta fish once in awhile.

First let me give color objectives:

1. Although you color wood, wood grain comes through for visual appealing effect.

2. Avoid weight of paint. Weight of dye is miniscule.

3. Specific to this yak, University of Hawaii colors.

Poque says:

If one were to use this information, your best bet would to be to color the wood before tacking, joining or anything else that involves epoxy

I agree completely. I didn't get on this bandwagon until I had done the butt joints. Fortunately after applying only fibreglass splice butt re-inforcement on one side, I recognized I should leave off outside hull splice until dye was applied. So if using wood dyes do them first as pogue says.

Pics (will come later) show epoxy sploches before I corrected some of them.

Note on red panel I had applied glass splice. It won't color up.

Two potential fixes. Dying glass when covering outside hull. OR ... Using epoxy dye.

I'll test glass dying solution, but think it will bleed just like wood. Not sure how you would get the dyed portion properly positioned anyway.

The dye in the epoxy itself should work as poque says..but I believe it will act like paint and block out wood grain. I can live with that in stitch holes and small section of this panel as it will be near waterline. We will see.

poque thanks for the tint source.

AL

I take it you want 2 colours to butt up against each other?

Yep. And due to complexity of doing colors have chosen to do separate panel colors as you also spotted as a solution.

Have you considered the dye you're using & a pinstripe to cover the bleeding?

Yes reflective tape stripping. But you never know how wide bleed will be.

Given that the dye is water based I don't see how you can stop the bleed without buggering yourself for the 2nd colour.

True enough. Why I went with separate panel colors

You could try scoring the outer layer however this will probably weaken the boat (Mat will know).

Can you use a different solvent with the dye? something that won't soak into the wood as easily?

Going to pass on those thought, but thanks for your ideas.

Mick & others I'll be adding more cross panels this week,

But man does not live by building boats. Gotta fish once in awhile.