Page 1 of 1

B C mistakes. measure twice cut once mess it up

Posted: Mon Jul 14, 2008 2:31 pm

by Bald Cypress

OK I followed directions, I thought. Measured carefully and cut on the lines.

Sanded down to the lines and then Butt joined.

Now looking at them, it seams WAY OFF.

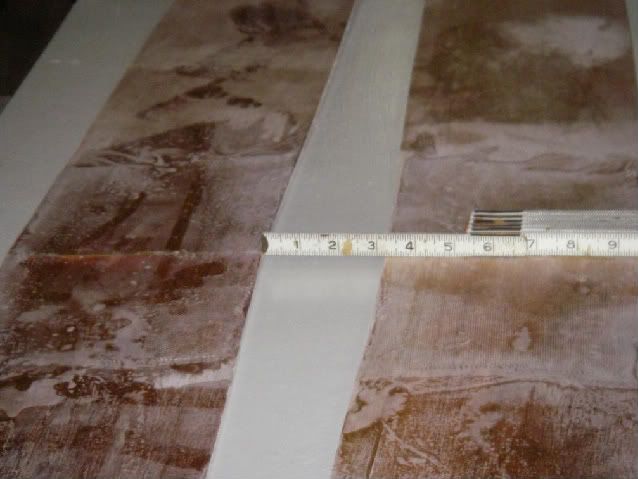

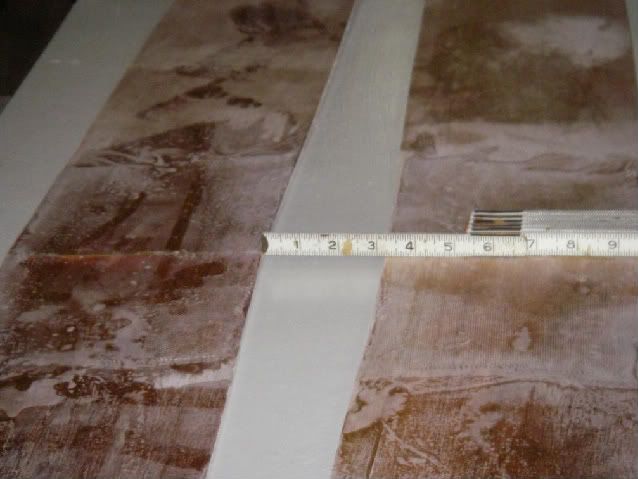

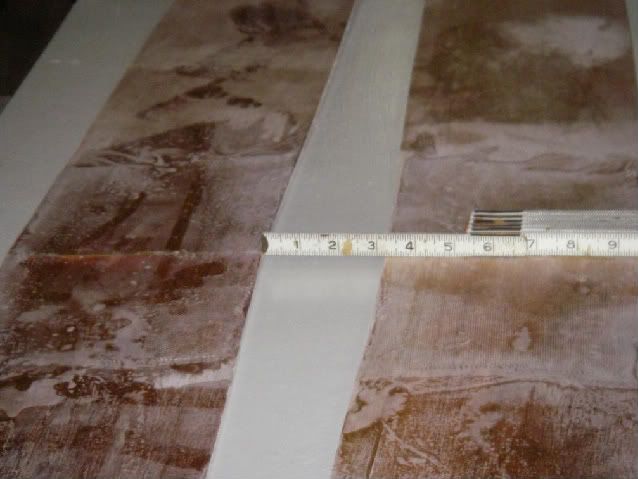

There is a 3.5 inch gap between the #1 pannels when layed out .

I am sure I followed the directions but, I must have misssed something someplace, I think.

Looking at the pics, does it look as if I measured and cut the mid point ends wrong ?

Where o where did I go wrong ?

Posted: Mon Jul 14, 2008 2:46 pm

by tx river rat

Bald

by the time the twist is in for the ends to come together and the built in rocker I bet they are right

Ron

Posted: Mon Jul 14, 2008 2:47 pm

by tx river rat

Bald

by the time the twist is in for the ends to come together and the built in rocker I bet they are right

Ron

Posted: Mon Jul 14, 2008 3:10 pm

by lark2004

If you are really worried, double check them with the QA measurments in your instructions. If it all measures up ok with them, then there's nothing to worry about.

Posted: Mon Jul 14, 2008 4:06 pm

by jem

Something doesn't look right. Shouldn't be that much of a gap. And where the panel joins, the transition looks funny. That could be just the angle of the shot.

Did you use both QA drawings?

You might want to try and redraw that panel on a scrap piece of wood and see how it looks compared to what you've done.

Posted: Tue Jul 15, 2008 6:49 am

by hairymick

G'day Baldy,

What boat are you building mate?

Something looks terribly wrong to me.

There are probably at least two sets of QA checks in your drawings - Check them with a string-line. lay your panels on the floor or at least on a flat surface that is big enough to hold AT LEAST the entire joined panels. These measurements are critical to the success of your build mate.

Posted: Thu Jul 17, 2008 8:17 pm

by Chalk

Where did you layout your lines? Did you start drawing from the butt splice at the edge of a panel?

What did you use to draw the long lines out? I use a sheet rock T square and knot free batten and cadre of wood sticks and clamps to draw the long curving lines out.

Your inside line should be somewhat square to the butt splice. How about a picture of the butt splice. The butt splice shouldn't be wide at one end either.

If your butt splice is somewhat square to the inside line, they way you laid out the long lines is probably the culprit.

Regardless of what is wrong, you can take a jig saw and cut the butt splice and fix it at the butt splice (Well, that's what I would do

) ..unless the long runs are bad wrong.

Whatever the problem is don't sweat it, it's boat building - not perfection...check your measurements you will get it figured out

Posted: Wed Jul 23, 2008 12:14 pm

by surfman

I'm with Chalk. Looks like you could lay a square at the butt splice and re-cut the joint square with the bottom of each panel. It is definitely not right. I would cut it square and then lay it out and check the measurement before I went to a lot of trouble re-gluing. That way if it turns out something else is wrong and you have to cut new pieces you wont waste time and epoxy re-gluing something wrong again.

Posted: Wed Jul 23, 2008 7:12 pm

by Chalk

You could actually layout the points on a sheet of plywood and lay the pieces on top of the layout to check them without cutting the splice.