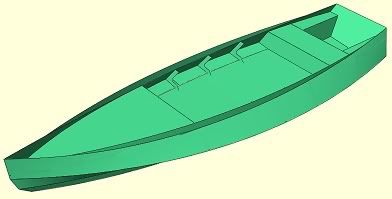

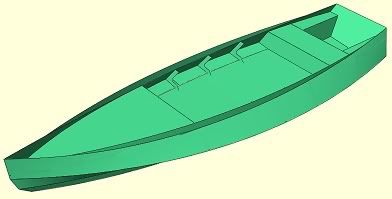

Buccaneer Xtreme (Prototype)

Posted: Fri Dec 31, 2004 8:19 pm

12/30/04 - I started laying out the frames, stringers and motor well panels today. This is a pretty complex little JEM of a boat  ....Here is a sneak peak of what I am gonna call "XXX"...

....Here is a sneak peak of what I am gonna call "XXX"...

I took pictures, but a sheet of luan with pencil markings is pretty boring ...I plan on cutting out some pieces tomorrow and will post some pictures...I am making templates with the luan because this is a prototype and I will use a router with the templates to make the final panels out marine plywood....

...I plan on cutting out some pieces tomorrow and will post some pictures...I am making templates with the luan because this is a prototype and I will use a router with the templates to make the final panels out marine plywood....

to be continued....

I took pictures, but a sheet of luan with pencil markings is pretty boring

to be continued....